Sejalo sa ho Sila Flour ea Koro

Kenyelletso e Khutšoanyane:

Sehlopha sena sa lisebelisoa se hlokomela ts'ebetso e tsoelang pele e tsoelang pele ho tloha ho hloekisa lijo-thollo tse tala, ho tlosoa ha majoe, ho sila, ho paka le kabo ea matla, ka ts'ebetso e boreleli le ts'ebetso e bonolo le tlhokomelo.E qoba lisebelisoa tsa khale tse sebelisang matla a phahameng mme e nka lisebelisoa tse ncha tse bolokang matla ho fokotsa tšebeliso ea matla ea mochini kaofela.

Lintlha tsa Sehlahisoa

Li-tag tsa Sehlahisoa

E Amanang le Video

Maikutlo (2)

Lintlha tsa Semela sa Wheat Flour Mill:

Tlhaloso ea Sehlahisoa

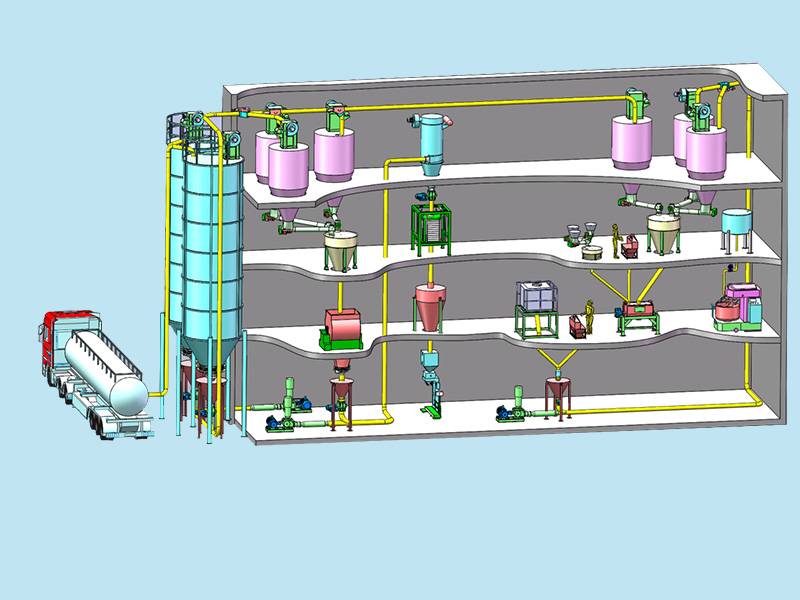

Sete e felletseng ea lisebelisoa tsa ho lokisa phofo ea boholo bo mahareng, e nang le mefuta ea lihlahisoa tsa lithane tse 100, 120, 150 le 200, e amohela sebopeho sa sebopeho sa moaho (mekato e 3-4), mme ts'ebetso ea tlhoekiso ea koro e tsoetse pele ebile e nepahetse, ke hore. e ka hloekisoa ka ho hloekisa kapa ho hloekisa metsi.Phofo e siloa ka leloala la phofo ea pneumatic e felletseng 'me e hlahlojoa ke planifter.Ho hloekisoa ha phofo ho kopantsoe le "spect detacher", 'me bran, semolina le masala li arohanngoa le ho homogenized, Ho sila ho bobebe le ho sila hantle ho ka hlahisa phofo ea sehlopha le phofo e khethehileng.Thepa e na le tekanyo e phahameng ea ho iketsetsa le ts'ebetso e tsitsitseng le e ka tšeptjoang.Fektheri e fana ka ts'ebeletso e le 'ngoe le morero oa ho fetola, e le hore basebelisi ba se ke ba tšoenyeha.

Sehlopha sena sa lisebelisoa se hlokomela ts'ebetso e tsoelang pele e tsoelang pele ho tloha ho hloekisa lijo-thollo tse tala, ho tlosoa ha majoe, ho sila, ho paka le kabo ea matla, ka ts'ebetso e boreleli le ts'ebetso e bonolo le tlhokomelo.E qoba lisebelisoa tsa khale tse sebelisang matla a phahameng mme e nka lisebelisoa tse ncha tse bolokang matla ho fokotsa tšebeliso ea matla ea mochini kaofela.

HLOEKISO KAROLO

.jpg)

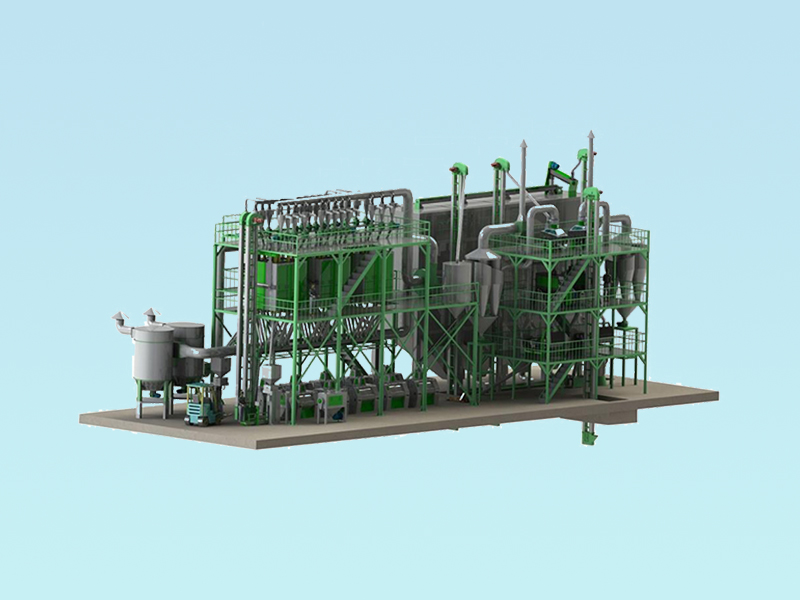

Karolong ea ho hloekisa, re sebelisa theknoloji ea ho hloekisa ea mofuta oa ho omisa. hangata e kenyelletsa ho sefa makhetlo a 2, ho hlapa ka makhetlo a 2, ho senya ka makhetlo a 2, ho hloekisa ka nako e le 'ngoe, ho hloeka ka makhetlo a 4, ho fokotsa makhetlo a 1 ho isa ho a 2, karohano ea matla a 3 joalo-joalo. Karolong ea ho hloekisa, ho na le litsamaiso tse 'maloa tsa aspiration tse ka fokotsang lerole le tsoang mochining le ho boloka tikoloho e ntle ea ho sebetsa. Ena ke letlapa le rarahaneng le ka tlosang boholo ba offal e mahoashe, offal ea boholo bo bohareng le offal e ntle. ka koro.Karolo ea ho hloekisa ha ea tšoanela feela koro e tsoang kantle ho naha e nang le mongobo o tlase mme hape e loketse koro e litšila e tsoang ho bareki ba lehae.

MOKHOA KAROLO

.jpg)

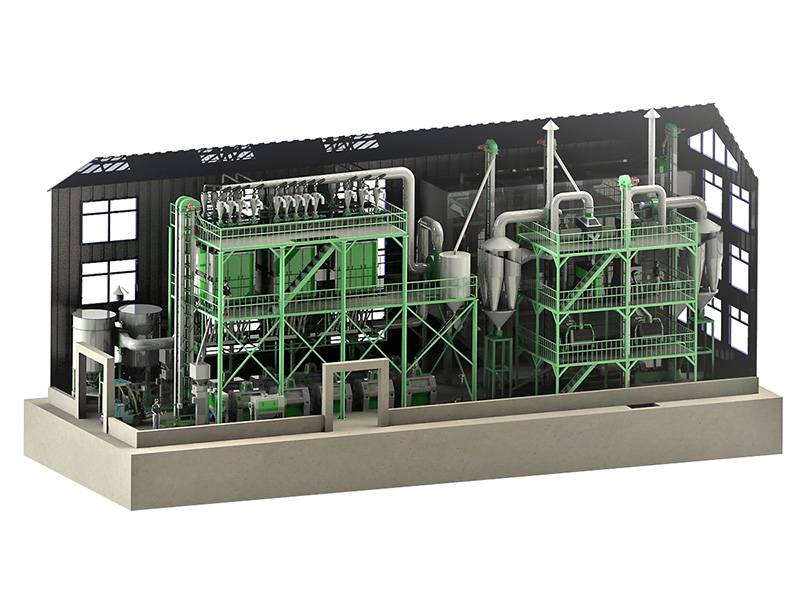

Karolong ea ho sila, ho na le mefuta e mene ea mekhoa ea ho sila koro hore e be phofo.Ke 4-Break system,7-Reduction system,1-Semolina system le 1-Tail system. ho Phokotso e ntlafatsang boleng ba phofo ka tekanyo e kholo.Lirolara bakeng sa Phokotso,Semolina, le Sistimi ea Mohatla ke lirolara tse boreleli tse phatlohileng hantle.Moetso oohle o tla etsa inshorense e fokolang ea bran e tsoakiloeng ka har'a bran mme tlhahiso ea phofo e eketsoe.Hobane Sistimi ea ho phahamisa moea e hlophisitsoeng hantle, lisebelisoa tsohle tsa leloala li fetisoa ke fan ea khatello e phahameng. Kamore ea ho sila e tla hloeka ebile e hloekile bakeng sa ho amoheloa.

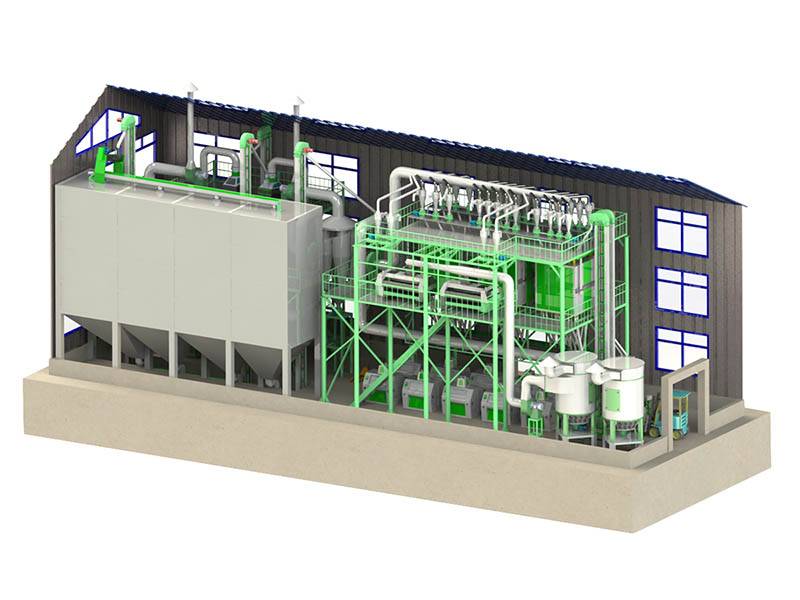

Mechini eohle ea ho paka ke automatioc.Mochini oa ho paka o na le likarolo tsa ho lekanya ho nepahetseng ho phahameng, lebelo la ho paka ka potlako, ho sebetsa ka botšepehi le ho tsitsitseng.E ka lekanya le ho bala ka mokhoa o itekanetseng, 'me e ka bokella boima.Mochine oa ho paka o na le mosebetsi oa ho itlhahloba ka phoso. Mochini oa ho roka o na le mokhoa o ikemetseng oa ho roka le oa ho itšeha. Mochini oa ho paka o na le mochini o tiisitsoeng oa mokotla oa mokotla, o ka thibelang thepa hore e se ke ea tsoa. Bareki ba ka khetha mefuta e fapaneng ea ho paka ho latela litlhoko.

Karolong ena, re tla fana ka khabinete ea taolo ea motlakase, thapo ea matšoao, literei tsa lithapo le litepisi tsa lithapo, le likarolo tse ling tsa ho kenya motlakase. Seteishene sa motlakase le thapo ea motlakase ha e kenyelelitsoe ntle le ho hlokoa ke moreki ka ho khetheha. Sistimi ea taolo ea PLC ke khetho ea boikhethelo bakeng sa moreki. Tsamaisong ea taolo ea PLC, mechini eohle e laoloa ke Programmed Logical Controller e ka tiisang hore mochini o sebetsa ka mokhoa o tsitsitseng le ka mokhoa o phollatsi. Sistimi e tla etsa likahlolo le ho etsa karabelo e nepahetseng ha mochini ofe kapa ofe o le phoso kapa o emisitsoe ka mokhoa o sa tloaelehang. alamo le ho hopotsa opareitara ho lokisa liphoso.Schneider series likarolo tsa motlakase li sebelisoa ka ntle ho khabinete ea motlakase.Letšoao la PLC e tla ba Siemens,Omron,Mitsubishi le Brand tse ling tsa machaba ho matha hantle.

LIEKETSENG PARAMETER LETHATA

| E fetotsoe | Bokhoni (t/24h) | Roller Mill e fetotsoe | Mohlala oa Sifter | Sekhoba LxWxH(m) |

| CTWM-40 | 40 | Bukana | Twin Sifter | 30X8X11 |

| CTWM-60 | 60 | Bukana | Twin Sifter | 35X8X11 |

| CTWM-80 | 80 | Moea oa moea | Plan Sifter | 38X10X11 |

| CTWM-100 | 100 | Moea oa moea | Plan Sifter | 42X10X11 |

| CTWM-120 | 120 | Moea oa moea | Plan Sifter | 46X10X11 |

| CTWM-150 | 150 | Moea oa moea | Plan Sifter | 50X10X11 |

Ho paka & Delivery

Litšoantšo tsa lintlha tsa sehlahisoa:

Tataiso e Amanang ea Sehlahisoa:

Re fana ka matla a matle ka boleng bo holimo le ntlafatso, thekiso, phaello le papatso le ts'ebetso ea Semela sa Wheat Flour Mill, Sehlahisoa se tla fana ka lefats'e ka bophara, joalo ka: Amman, Istanbul, Italy, Ka litharollo tse ntle haholo, litšebeletso tsa boleng bo holimo. Boikutlo ba 'nete ba ts'ebeletso, re netefatsa khotsofalo ea bareki le ho thusa bareki ho theha boleng molemong oa bobeli le ho theha maemo a win-win.Amohela bareki lefatšeng ka bophara ho ikopanya le rona kapa ho etela k'hamphani ea rona.Re tla u khotsofatsa ka tšebeletso ea rona e tšoanelehang!

Fektheri e ka kopana le litlhoko tse tsoelang pele tsa moruo le tsa mebaraka, e le hore lihlahisoa tsa bona li tsejoe ka bongata le ho tšeptjoa, ke ka lebaka leo re khethileng k'hamphani ena.